In medium-scale projects such as municipal road construction, rural infrastructure, and loading and unloading in logistics parks, the mobility, operating efficiency, and durability of wheel excavators directly impact construction progress and operating costs. LUYU wheel excavators, with their targeted technical design, precisely address these core challenges, making them the preferred choice for many users. Based on actual jobsite requirements, let's break down its four key advantages and see how it helps projects improve efficiency and reduce costs.

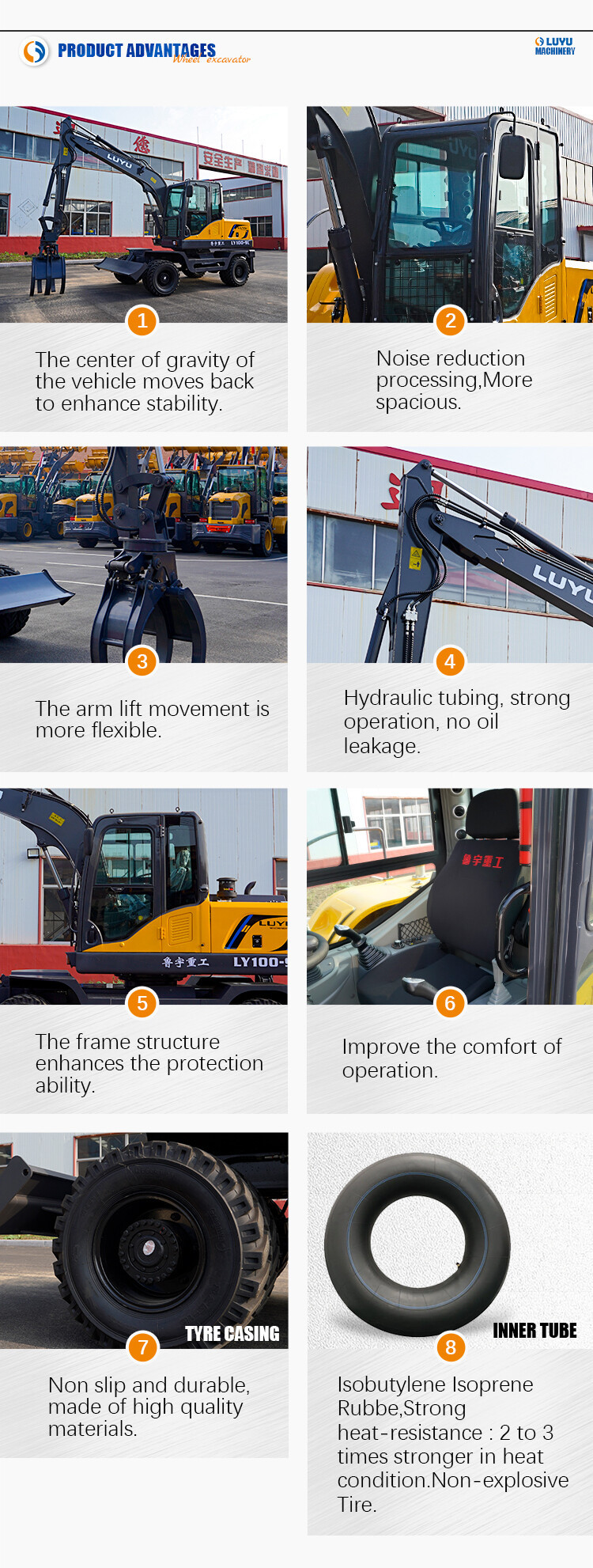

1. Rapid Mobility & Strong Off-Road Performance

LUYU wheel excavators are equipped with imported drive axles and transmissions. With a powerful full-time four-wheel drive system, they can cross ditches and uneven terrain without damaging the undercarriage. Even on rugged jobsite roads, they maintain stable travel, preventing delays caused by poor ground conditions—making them a true off-road powerhouse.

2. High-Efficiency Power & Intelligent Fuel Control

In terms of power, LUYU wheel excavators are equipped with engines from leading brands such as Kubota and Cummins, delivering abundant power reserves and strong performance. Paired with LUYU's self-developed optimized bucket, they can load a truck within just a few minutes. On fuel efficiency, the electronically controlled positive flow system allocates power on demand, saving a significant amount of fuel costs over the course of a year and greatly reducing overall operating expenses.

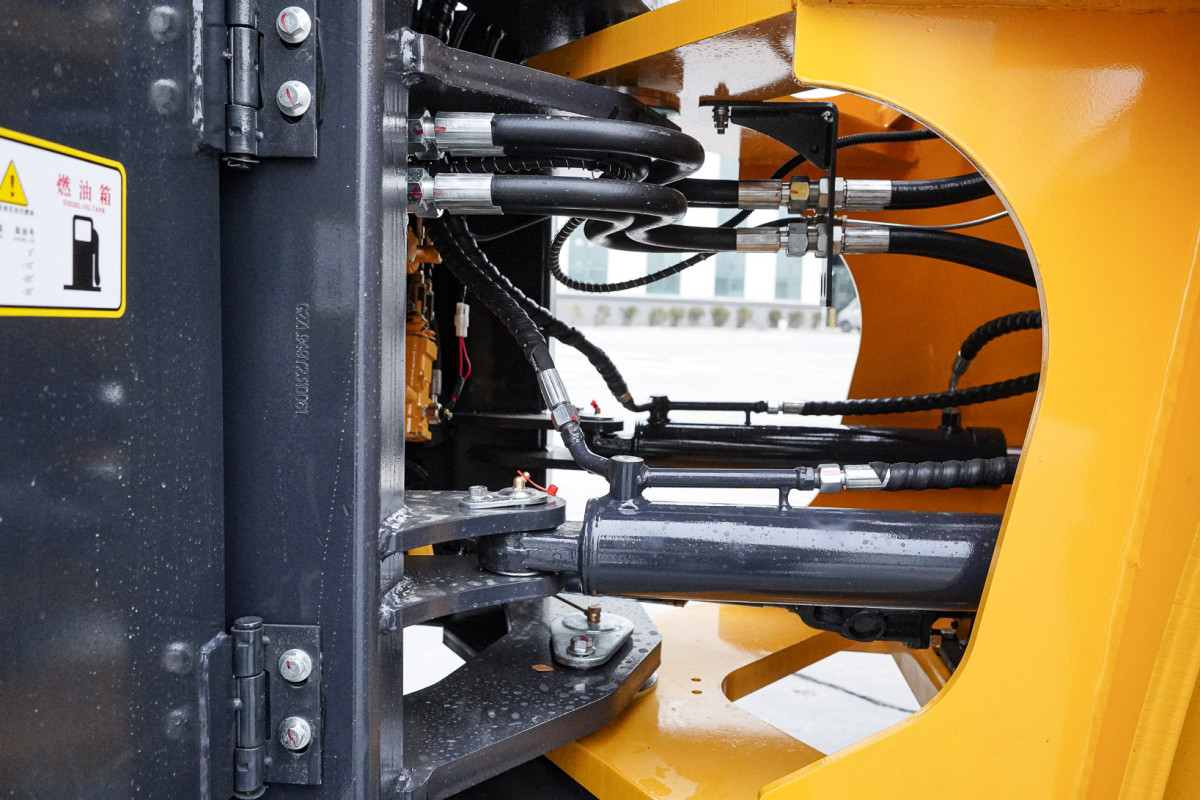

3. Wear-Resistant Structure & Detail Protection

The "durability" of a wheel excavator directly affects long-term operating costs. LUYU wheel excavators feature reinforced designs on easily worn components and key structures. The bucket adopts a "double-arc optimized" profile, while the front cutting edge uses LUYU's unique "flanged structure," significantly enhancing reliability. In addition, new dust-proof seals and honeycomb high-load wear-resistant bushings provide meticulous protection, ensuring long service life with minimal maintenance.

4. Comfortable Operation & User-Friendly Design

The real-time display shows fuel consumption and operating status, with a rear-view camera for safer maneuvering. A one-touch start system and optimized control panel make it easy for new operators to get started. The upgraded air-conditioning ducts increase airflow by 30%, cooling the cabin within 10 minutes. Shock-absorbing seats reduce vibration by 30%, allowing operators to work continuously for 8 hours without back strain. No downtime between shifts, ensuring long hours of operation without fatigue.