The main bearing of the ball mill is one of the important components of the ball mill, which has an important influence on the operation efficiency of the ball mill.

Under the high temperature in summer, the main bearing of the ball mill is prone to high temperature of the bearing pad, and even a bearing accident in severe cases. In this article, we will discuss how to solve the problem of the high temperature of the bearing pad of the main bearing of the ball mill.

1. Replace the ball mill lubricating oil in time

During the operation of the ball mill, heat is generated due to the relative rotational friction between the hollow shaft and the bearing bush, which increases the temperature of the main bearing. Therefore, the friction can be reduced by replacing the lubricating oil, so that a uniform oil film can be formed on the bearing surface. Avoid increasing the temperature of the main bearing.

2. Adjust the cooling water and cooling device of the ball mill

The cooling of the ball mill is very important. The cooling water in the main bearing bush and the water in the main bearing oil tank cooler are the two main waters for the main bearing of the ball mill. The temperature of the cooling water has a great influence on the temperature of the main bearing of the ball mill, and the temperature of the cooling water is low. The cooling effect of the lubricating oil is fast and the cooling effect is good. Increasing the cooling water flow will also reduce the temperature of the main bearing bush.

3. Improve the environmental conditions of the ball mill

The temperature of the ball mill itself is greatly affected by the surrounding environment. In summer, the ambient temperature is high, and the temperature of the bearing bush of the ball mill is also high. The doors and windows of the factory building, the doors and windows of the oil pump room and the observation hole of the large tile should be opened to improve the ventilation conditions of the environment where the ball mill is located and reduce the temperature of the lubricating oil.

In addition, if conditions permit, an axial flow fan can be installed in the oil pump station to increase the circulating flow of air and reduce the temperature of the lubricating oil. The temperature can also be reduced by adding spray water to the oil return pipe and the oil outlet pipe.

4. Increase the cooling area of the oil pump

The cooler in the ball mill oil pump can be re-selected, or the cooling area of the ball mill lubricating oil can be increased by connecting the cooler in series, the heat exchange effect of the ball mill lubricating oil can be improved, and the temperature of the lubricating oil fed into the ball mill can be reduced. reduce bearing temperature

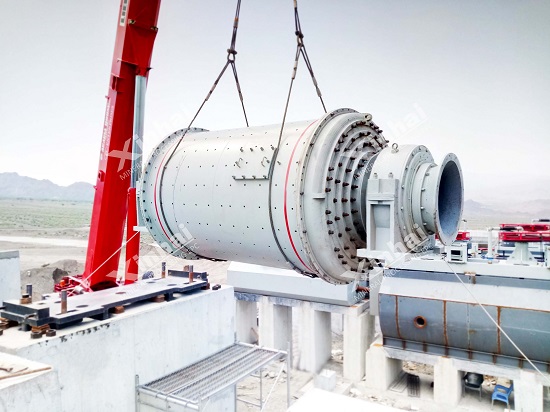

Below are the parameters of some of our ball mills for your reference