INQUIRY

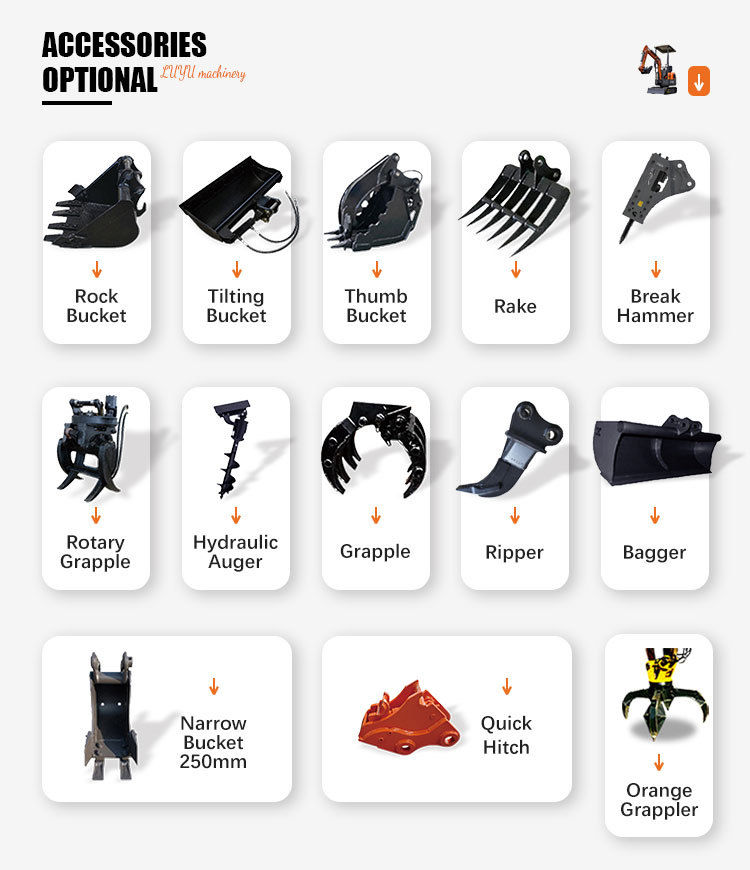

The 1-2 ton excavator belongs to the category of mini/small excavators, which are lightweight and compact, and are suitable for narrow or indoor working scenarios. These machines usually use a hydraulic drive system, which is both flexible and versatile, and can realize various functions such as digging, crushing and bulldozing by replacing attachments.

Main application scenes

1.Municipal engineering: such as pipeline laying, cable excavation, road surface crushing, etc.

2. Agriculture and gardening: orchard reclamation, vegetable greenhouse renovation, farm construction, etc.

3. Construction assistance: indoor demolition, foundation backfill, narrow space construction.

4. Special environment: tunnel construction, mine operation, river dredging

Choosing LUYU is choosing quality

1. Patented Advanced Dynamic Hydraulic Technology

LUDV Dynamic Balance Hydraulic System - Achieves a 20% improvement in operational responsiveness and a 15% optimization of fuel efficiency (the document explicitly mentions that the system is applied to all models). Most competitors use traditional fixed-displacement hydraulic systems, which are difficult to match in terms of energy efficiency and precision.

2. Ultra-narrow space-adaptable structural design - Intelligent adjustment range of track spacing up to ±30%, narrow space passability up to 40% higher than the industry standard

3. Military-grade welding process - Panasonic collaborative robot welding + laser dynamic calibration. Welding seam density reaches 4.2mm/㎝² (3.0mm/㎝² for common process), which is rare in the industry.

4. Urban Silent Solution-Multi-layer composite acoustic envelope technology, air vibration isolation rate reaches 95%.

5. All-weather Powertrain Configuration-Cold-start Enhancement Package. With multi-channel thermal management system, the hydraulic oil temperature fluctuation is no more than ±5℃ under extreme working conditions.

6. rigorous quality control system - factory qualified standard higher than ISO requirements of 12%, failure rate of less than 0.3 times / thousand hours (industry average 0.8 times).

Our Services

Whether it is pre-sales consultation or after-sales protection, we will provide 100% service enthusiasm!