Mini-excavators with CE (Conformité Européenne) certification and Euro V emission standards are typically designed to meet the safety and environmental requirements of the European market.

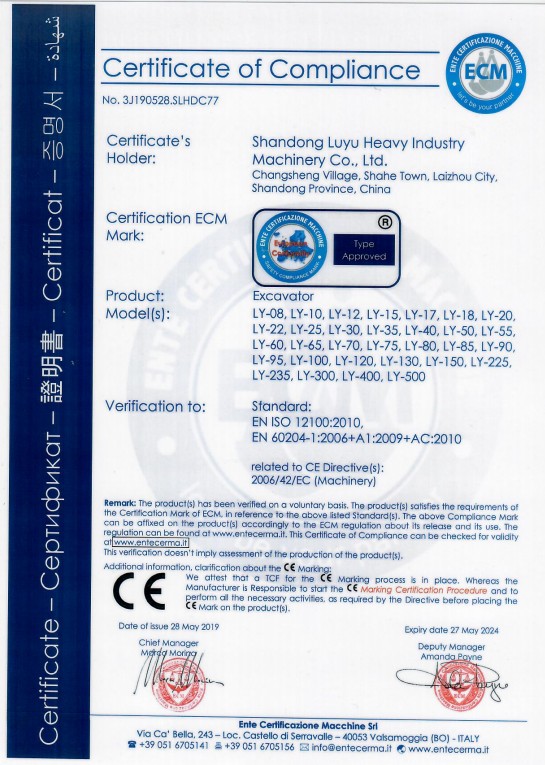

Many of LUYU's excavator products have obtained the following certifications

✅CE certification: Complies with the EU Machinery Safety Directive, ensuring the legal sale of equipment in the European market.

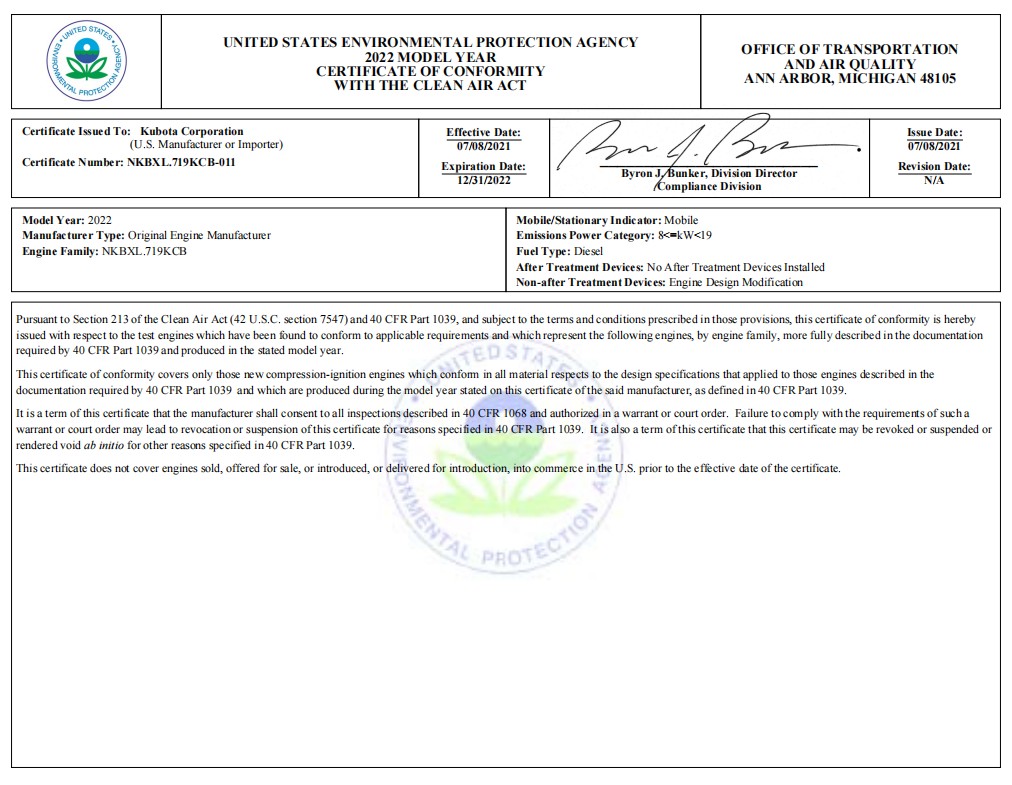

✅Euro V Emission Standard: Meets the EU Non-Road Mobile Machinery (NRMM) Stage V emission requirements, applicable to diesel engines with power between 19kW and 560kW.

These certifications ensure that LUYU excavators meet the high standards of the European market in terms of safety and environmental protection. Mini-excavators with CE (Conformité Européenne) certification and Euro V emission standards are usually designed to meet the safety and environmental requirements of the European market.

✅一、CE certification

Scope of application: All machinery and equipment entering the EU market for sale

Significance for excavators:

It indicates that the excavator complies with the EU Machinery Directive 2006/42/EC, EMC Directive, Noise Directive and other relevant regulations;

It mainly covers: mechanical safety, electrical system safety, control system reliability, operator protection, etc.;

Excavators CE marking, technical documentation, and Declaration of Conformity (DoC) are required. Many LUYU excavator products have obtained the following certifications:

CE Certification: Complies with the EU Machinery Safety Directive and ensures the legal sale of equipment in the European market.

Euro V Emission Standard: Meets the EU Non-Road Mobile Machinery (NRMM) Stage V emission requirements for diesel engines with power between 19kW and 560kW.

These certifications ensure that LUYU excavators meet the high standards of the European market in terms of safety and environmental protection. Mini-excavators with CE (Conformité Européenne) certification and Euro V emission standards are usually designed to meet the safety and environmental requirements of the European market.

✅二、Euro V emission standard (Stage V)

Scope of application: non-road mobile machinery (NRMM), such as excavators, loaders, forklift trucks, etc.

Applicable regulations: European Union Regulation (EU) 2016/1628

Significance for excavators:

Requires low engine emissions of nitrogen oxides (NOx), hydrocarbons (HC), particulate matter (PM);

Mainly applies to diesel engines between 19kW and 560kW;

Emission control devices such as DPF (Diesel Particulate Filter), EGR, SCR (Urea System) must be installed;

The engine must be certified and obtain the “Emission Type Approval Certificate”. CE certification

Scope of application: All mechanical equipment entering the EU market

Significance for excavators:

indicates that the excavator complies with the EU Machinery Directive (Machinery Directive 2006/42/EC), the EMC Directive, the Noise Directive and other relevant regulations;

mainly covers: mechanical safety, electrical system safety, control system reliability, operator protection, etc.; the excavator needs to affix CE certification to the CE certificate; the excavator needs to affix CE certification to the CE certificate. Mainly covering: mechanical safety, electrical system safety, control system reliability, operator protection, etc.;

Excavators are required to affix the CE marking and have technical documents and Declaration of Conformity (DoC). Many excavator products of LUYU have obtained the following certificates:

CE certification: conforms to the European Union's Machinery Safety Directive to ensure that the equipment can be sold legally on the European market.

Euro V Emission Standard: Meets the EU Non-Road Mobile Machinery (NRMM) Stage V emission requirements for diesel engines with power between 19kW and 560kW.

These certifications ensure that LUYU excavators meet the high standards of the European market in terms of safety and environmental protection. Mini-excavators with CE (Conformité Européenne) certification and Euro V emission standards are usually designed to meet the safety and environmental requirements of the European market.

✅三、LUYU Excavator Models with CE and Euro V Approvals

The following are some of the LUYU excavator models with CE and Euro V approvals:

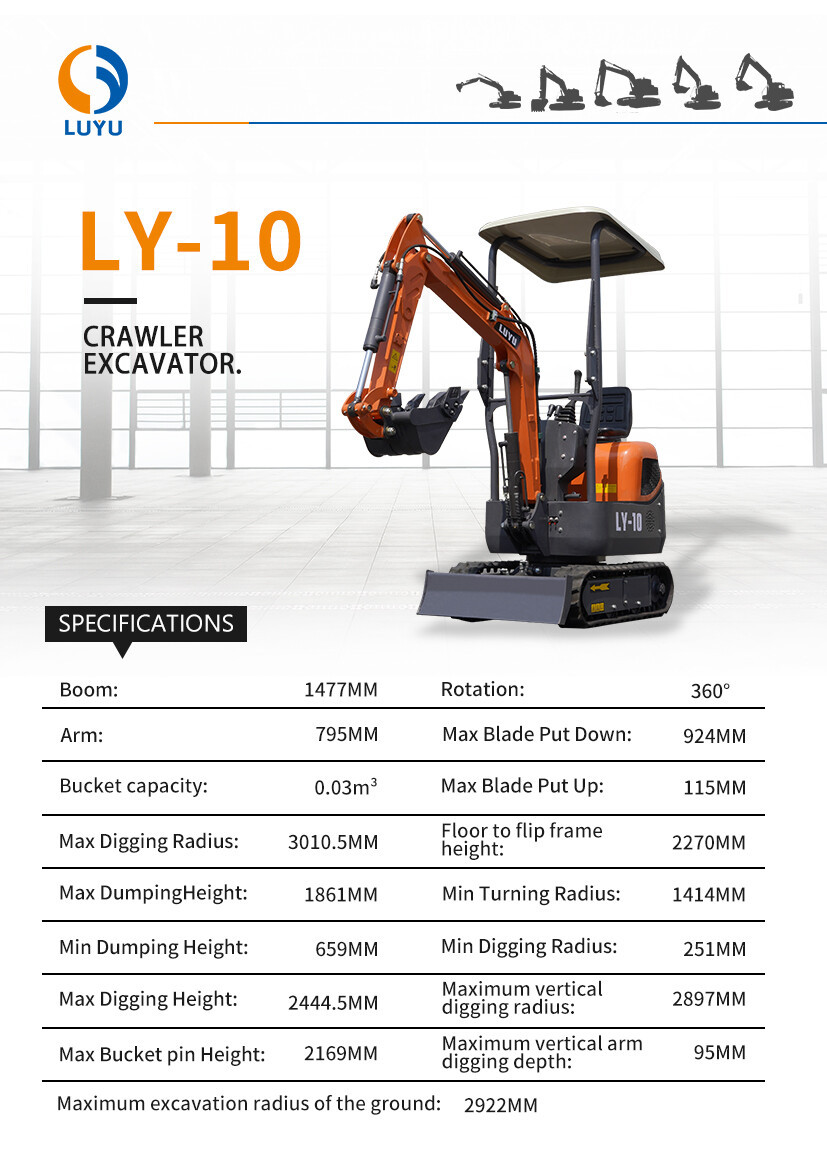

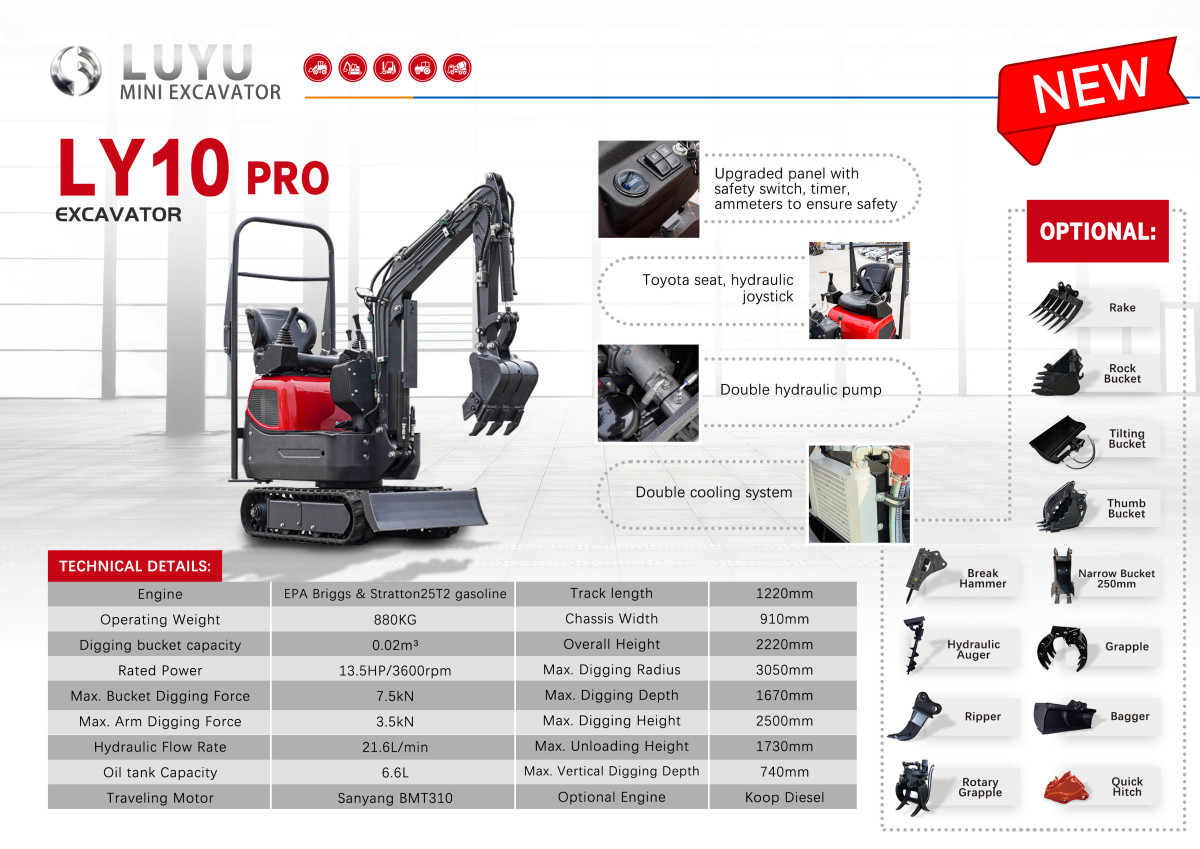

LY10 1-ton mini crawler excavator:

Engine: KOOP 192F, power 7.6kW.

Characteristics: Compact and flexible, suitable for working in narrow space, compliant with CE and Euro V standards.

LY20 2-ton miniature crawler excavator:

Engine: Optional Euro V compliant diesel engine.

Characteristics: Suitable for small and medium-sized projects, with good working performance and environmental performance.

LY35 3.5-ton crawler excavator:

Engine: Kubota, power 18.5kW.

Features: sturdy structure, suitable for various construction environments, meets CE and Euro V standards.

LY135Z 13.5 tons wheeled excavator:

Engine: YUCHAI, power 62.5kW.

Characteristics: Suitable for large-scale construction projects, with high efficiency and environmental performance.

Second, Euro V emission standard (Stage V)

Scope of application: non-road mobile machinery (NRMM), such as excavators, loaders, forklifts, etc.

Applicable regulations: European Union Regulation (EU) 2016/1628

Significance for excavators:

Requires low engine emissions of nitrogen oxides (NOx), hydrocarbons (HC), particulate matter (PM);

Mainly applies to diesel engines between 19kW and 560kW;

Emission control devices such as DPF (diesel particulate filter), EGR, SCR (urea system) must be installed.

✅四、Purchasing Suggestions

If you plan to purchase mini excavators with CE and Euro V certifications, it is recommended to:

Confirm the certification documents: Ask the supplier for the CE Declaration of Conformity (DoC) and Euro V engine certification documents.

Define the use and demand: choose the right model and configuration according to the project demand.

Choose regular channels: Purchase through LUYU's officially authorized dealers or certified agents to ensure product quality and after-sales service.

Pay attention to the difference between models: the same model may have an export version (with CE/Euro V) and a domestic version (National IV or National III), make sure to check the certification status of the purchased model.