When choosing a forklift, you should decide which type of forklift to use based on the specific work environment and needs. Rough terrain forklifts, while more expensive, have obvious advantages in situations that require frequent movement and dealing with complex terrain. However, ordinary forklifts may be more competitive in terms of cost and maintenance, especially in flat and stable work environments. It is advisable to conduct detailed field tests before purchase to ensure that the chosen forklift can meet the actual work requirements.

1. Driving mode and passability

Rough terrain forklift: four-wheel drive, equipped with large-diameter, wide-based off-road tires, ground clearance of more than 300mm, with excellent passability and off-road, suitable for use in complex terrain such as hills, mountains, beaches, sand, snow, ice and muddy roads.

Ordinary forklift: usually two-wheel drive, low chassis, small size, mainly used in flat and solid paved occasions, such as factories and enterprises.

2. Stability and operation movement

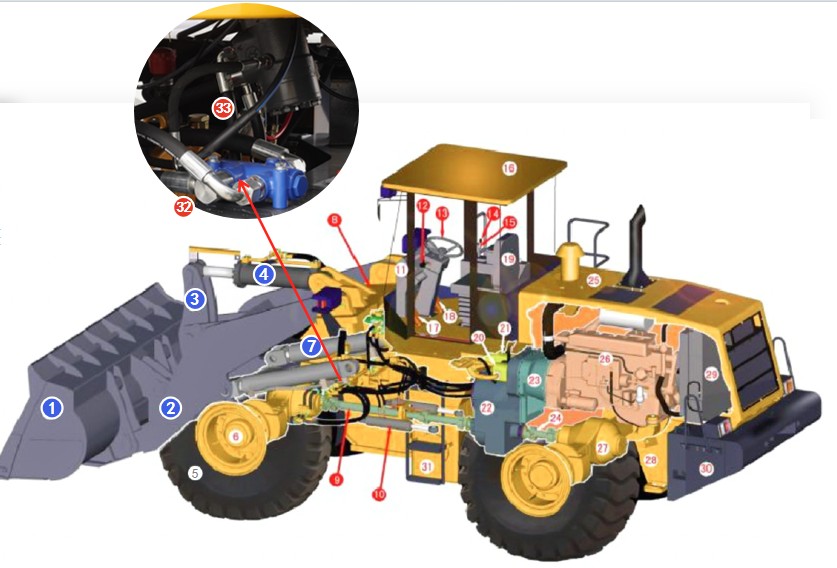

Rough terrain forklift: due to the high chassis, the center of gravity is also high, but the wheelbase and wheelbase are longer and wider, which enhances the stability in uneven places. In addition, it has multi-stage buffer system, such as tires, cab suspension, shock-absorbing seat and full-floating transmission system, which further reduces engine vibration and improves driving comfort.

Ordinary forklift: poor stability, mainly vertical movement, not suitable for side shift operation.

3. Engine power and applicable scenes

Rough terrain forklift: with high engine power, all-wheel drive and cross-country tires, it is able to drive under various complicated road conditions, especially suitable for use in the field, mine, construction site, mud, mudflat, mountain and sandy road.

Ordinary forklift: the engine power is relatively small, more suitable for use in flat and with solid road surface.

4. Reliability and Durability

Rough Terrain Forklift Trucks: Used in harsh environments such as the wild, they require higher durability and reliability, such as reinforced gantries, drive and steering axles, and fully enclosed wet brakes to ensure stability and safety under extreme conditions.

Ordinary Forklift Trucks: Although they perform well indoors or in flat environments, they may not be durable enough in harsh conditions.