In the small loader market, the 3-ton model has become the first choice of many users with its unique advantages. Whether it is a construction site, farmland operation or logistics warehousing, 3 tons of small loaders can easily cope with. luyu will provide you with a comprehensive analysis of why 3 tons small loaders are so popular from the comparison with other tonnage models, domestic and international industry situation and product advantages and selling points.

| Engine type | Yuchai6105T 92KW/123HP |

| Bucket capacity | 1.5m³ |

| Dumping height | 3800mm |

| Rated load | 3000kg |

| Total weight | 8580kg |

| Bucket width | 2400mm |

| Overall size | 7550*2470*3350mm |

| Minimum ground clearance | 430mm |

| Tyre | 17.5-25 |

Comparison of 3-ton compact loader with other tonnage models

1. Comparison with 1-2 tons models

Although 1-2 ton compact loaders are more lightweight and flexible, they are slightly less powerful and capable. In contrast, the 3-ton mini-loader offers more digging power and carrying capacity while maintaining a higher degree of flexibility, making it suitable for medium-intensity work tasks.

2. Comparison with 4-5 tons models

Although the 4-5 ton compact loader is more powerful and suitable for heavy-duty work, it is larger, less flexible, and has higher fuel consumption and

maintenance costs. 3 ton compact loader strikes a perfect balance between power and flexibility, which meets most of the operational needs without wasting resources.

3. Comparison of applicable scenes

1-2 tons model: suitable for light work, such as small farms, warehouse handling, etc.

3-ton model: suitable for medium-intensity work, such as construction sites, medium-sized farms.

4-5 tons model: suitable for heavy-duty work, such as mines, large construction sites, etc.

Global 3-ton compact loader industry situation

1. China Market

In China, 3 ton compact loader has become a popular choice for small and medium-sized enterprises and self-employed people due to its cost-effectiveness

and wide range of applications. In recent years, with the acceleration of rural construction and urbanization, the demand for 3-ton compact loaders continues to grow. Through technological innovation and cost control, Chinese brands have launched a variety of high-quality, low-cost 3-ton models, which are favored by users.

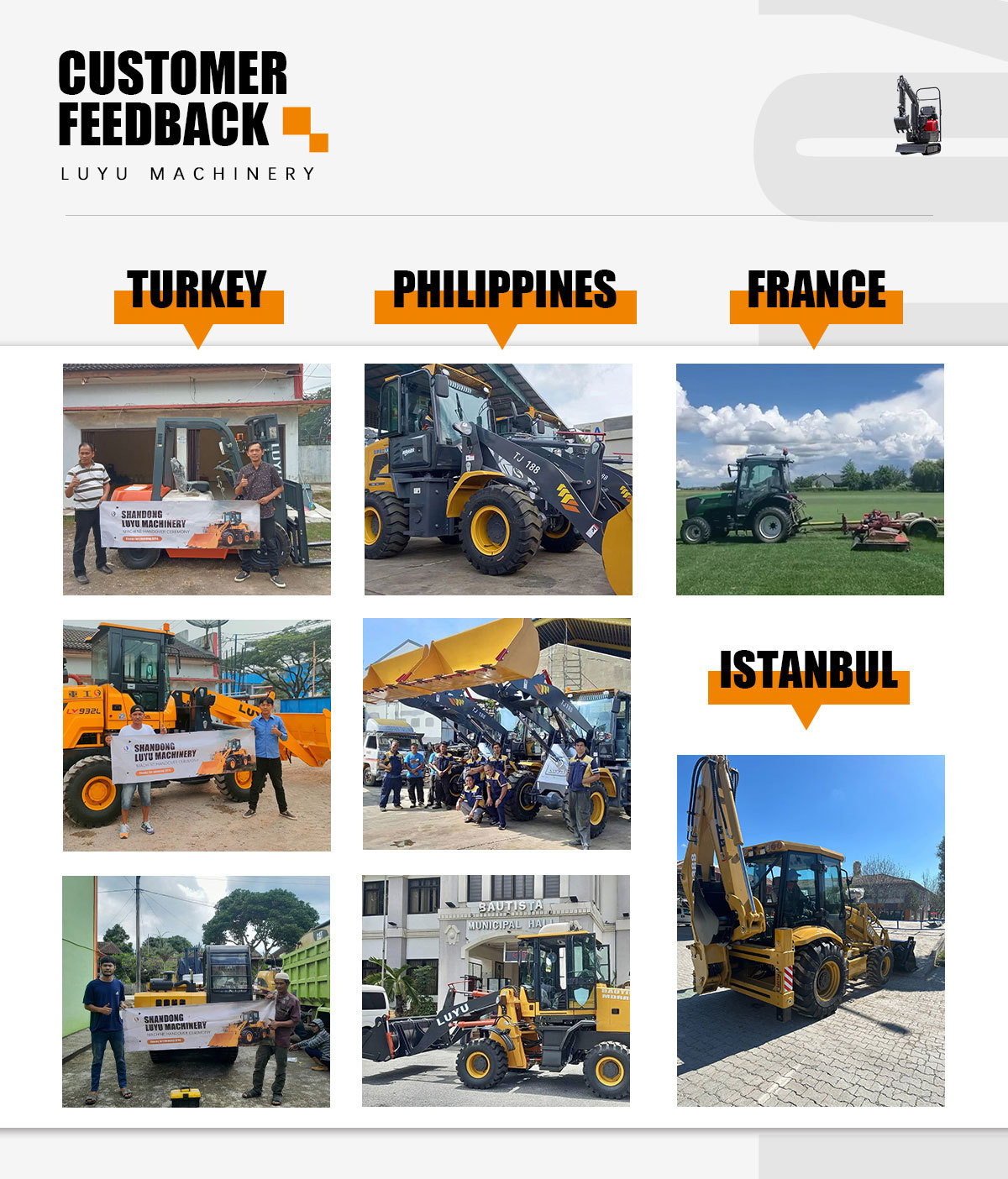

2. International market

In the international market, 3-ton compact loaders are also attracting attention. Europe and the United States focus on the environmental protection and

intelligence of the equipment, and many international brands have launched 3-ton models that meet the latest emission standards. Meanwhile, the demand for 3-ton compact loaders in developing countries is also growing rapidly, mainly for infrastructure construction and agricultural production.

Advantageous selling points of 3 tons compact loader

1. Flexibility and efficiency at the same time

The modest size of the 3-ton compact loader allows it to operate flexibly in confined spaces while providing enough power to accomplish moderately intense tasks. For example, the turning radius of a certain 3-ton loader is only 4 meters, which is ideal for operating in complex environments.

2. Low cost, high return

Compared with larger tonnage models, 3-ton compact loaders have lower purchase and operating costs. Its fuel consumption and maintenance costs are more

economical, making it suitable for users with limited budgets. At the same time, its efficient operating capacity can quickly return to the capital, creating more value for users.

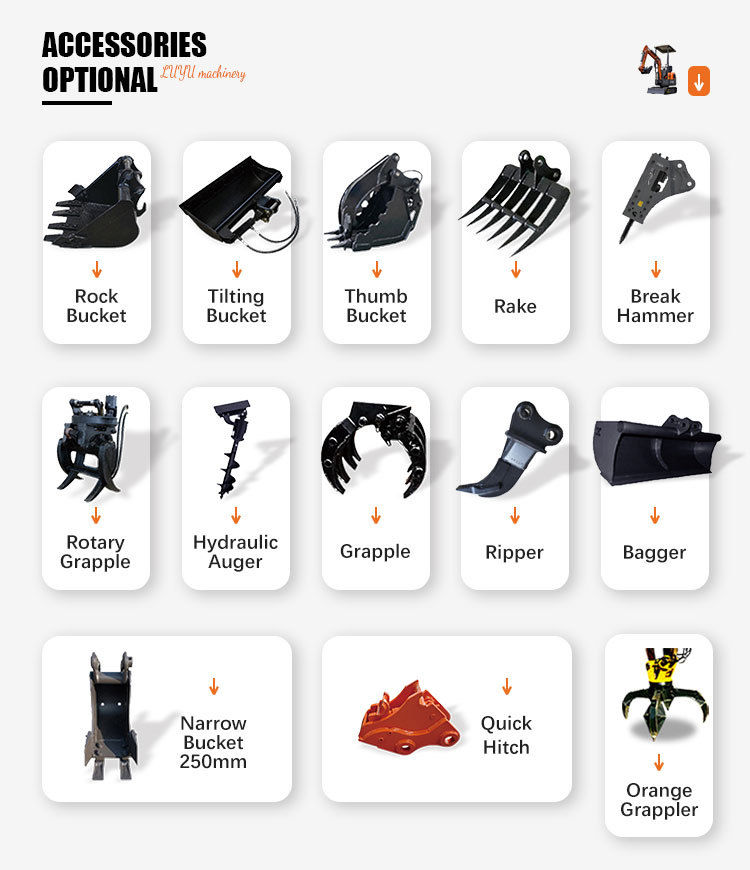

3. Multi-functionalit

3 tons of small loaders are usually equipped with a variety of attachments, such as buckets, forklift frames, hydraulic hammers, etc., to adapt to different

operational needs. This multifunctionality not only improves the utilization rate of the equipment, but also saves the user the cost of purchasing additional equipment.

4. Durability and reliability

High-quality 3-ton compact loaders use high-quality materials and precision manufacturing processes to ensure that the equipment still maintains a long life

in harsh environments.

5. Intelligent and environmental protection

With the development of technology, many 3-ton compact loaders are equipped with intelligent control systems, such as automatic leveling, remote monitoring

and other functions, which further enhance the operational convenience and safety. At the same time, the engine that meets the latest emission standards also reduces environmental pollution and meets the needs of modern users for environmental protection.

With its flexibility, efficiency and versatility, the 3-ton compact loader has become the ideal choice for small and medium-sized operation scenarios.The 3-ton model shows strong competitiveness and broad prospects for development. If you are looking for a machine that can meet your operational needs and is also economical, the 3-ton compact loader is undoubtedly your best choice.