Forklift trucks are indispensable right-hand men in warehouses and factories, and electric forklifts are becoming more and more popular because of their environmentally friendly and low operating costs.But there are all kinds of electric forklifts on the market. How to choose?

Define the needs of the assignment

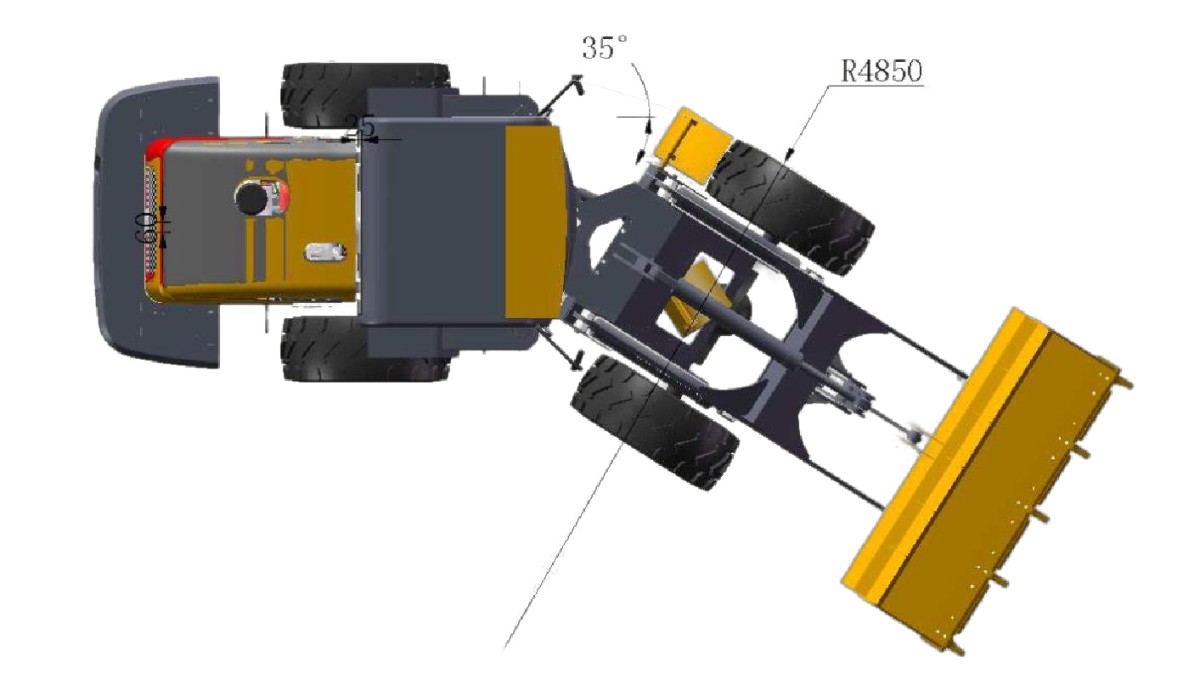

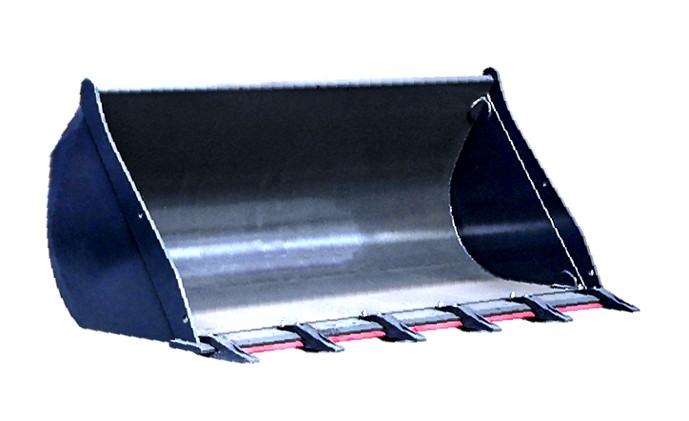

First of all, you have to figure out what you usually do. If the main indoor warehouse to move small objects, like the kind of e-commerce warehouse, choose a small and flexible narrow-channel electric forklift. It's easy to maneuver between shelves. If in the construction site, to carry heavy construction materials. Then you have to pick a lifting weight, strong power of the electric forklift. Otherwise you won't be able to do the heavy lifting. For example, if you often have to carry about 1 ton of goods, the forklift you choose must have a lifting weight of at least 1.5 tons. Allow for some margin to make it more stable.

Measuring Battery Performance

Electric forklift trucks rely on battery power, battery performance is too important. First look at the battery capacity, the larger the capacity, the longer the range. If your working hours are long, like working continuously for more than 8 hours a day, choose the forklift with high capacity battery. Reduce the number of charging times, improve work efficiency. You also need to pay attention to the charging speed of the battery. Fast charging technology allows you to get to work faster. In addition, the life of the battery must also be considered, long-life battery replacement cost is low.

Focus on brand and after-sales service

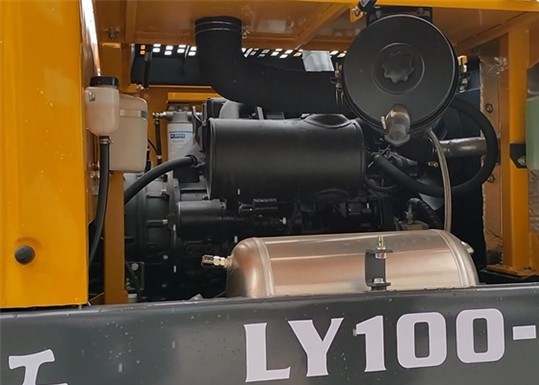

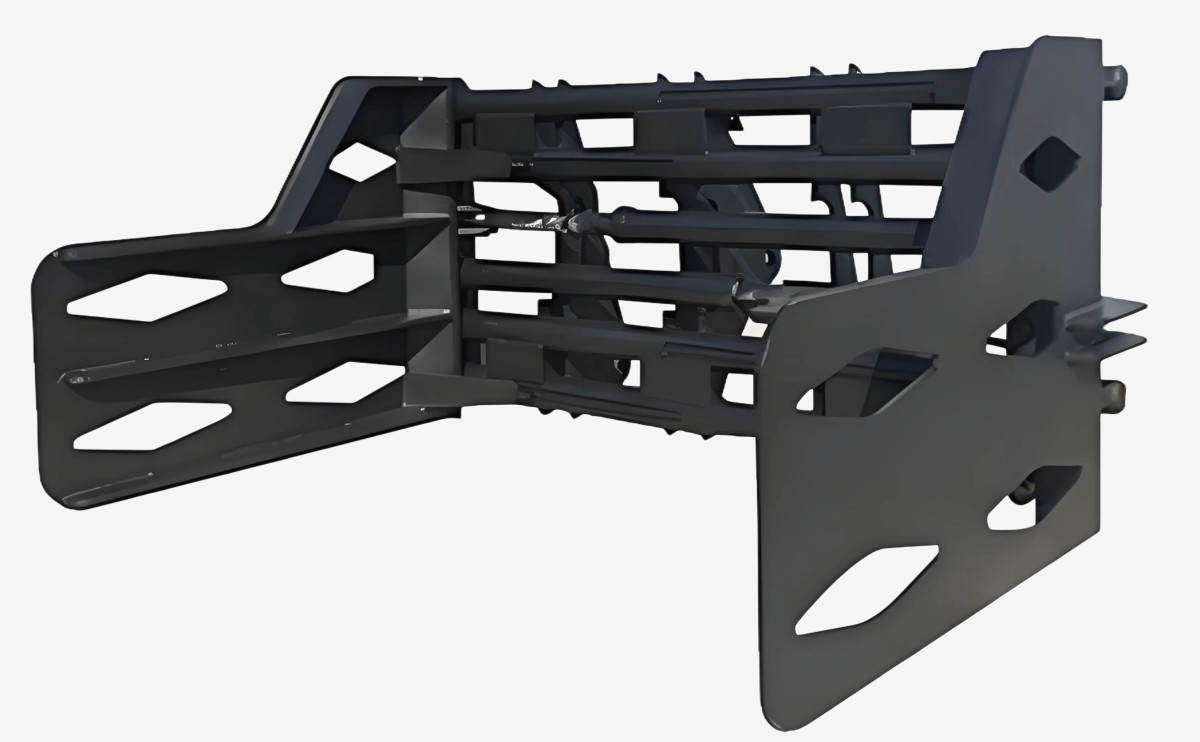

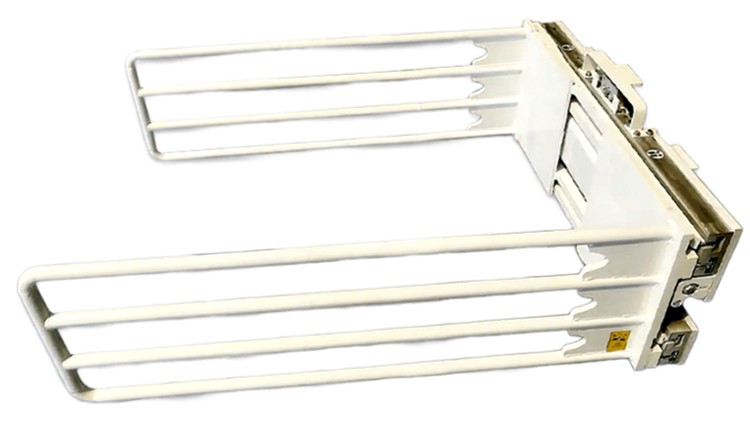

The quality of electric forklifts of big brands is relatively more guaranteed. Like LUYU, the production process is mature, product quality is stable.

Operator comfort and safety

Anyone who drives a forklift knows that operator comfort is important. The seat should be comfortable, preferably adjustable, and the steering wheel should be flexible. Then there is safety, forklift trucks must have overload protection, emergency braking and other safety devices. For example, when handling goods, if overweight, overload protection device can timely alarm to avoid danger.

To summarize some of the suggestions above, we recommend that you choose LUYU Electric Forks. We have absolutely strong technical and R&D capabilities, as well as reliable after-sales service. We believe that we can provide convenience for your life.